|

Technology Soldering under vacuum Soldering under vacuum is a technology that provides excellent results for all soldering applications. Vacuum is used in several places during the process execution:

Void-free solder joints

Fluxless soldering using formic acid

The possibility to use formic acid (HCOOH) in combination with

Nitrogen results in a cost-efficient and stable soldering

process, reducing oxide film formation while no fluxing agent is

needed in the process. The formic acid surface activation

provides good results with respect to void rate across the

surface.

The formic acid (enriched with Nitrogen) removes oxide films, which inhibit the soldering process. The formic acid is applied by a bubbler, integrated in the machine. Nitrogen is blown through the bubbler, where it is enriched with formic acid and released into the chamber. How does the chemical reaction work? Metal Oxide + HCOOH -> Metal + CO2 +H2O At temperature over 150-200°C the metal oxide film on the surface is reduced to clean metal surface. The gaseous products CO2 and water are simply purged with dry nitrogen and exhausted to the atmosphere. The advantages of this process are the following:

Systems

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

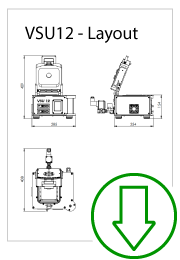

VSU 12 Programmable vacuum soldering oven with a heating area of 100mm x 100mm

|

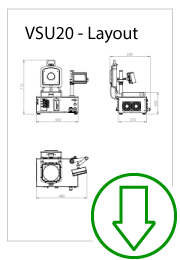

VSU 20 Programmable vacuum soldering oven with a heating area of 200mm diameter

|

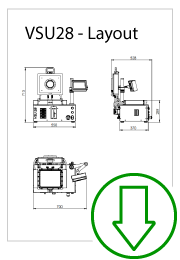

VSU 28 Programmable vacuum soldering & brazing oven with a heating area of 260mm x 210mm

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Highlights

|

Highlights

|

Highlights

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Overview

Infrared lamps placed under the tooling plate

heat it up. The tooling plate has a square form with dimensions

100mm x 100mm and can be made of any suitable material. It can also

be prefabricated with custom openings for fixtures inside it. The

tooling plate can be replaced together with the parts on it. This

enables serial production. Nitrogen flow blows from the chamber

bottom against the tooling plate and thus cools it down. The chamber

itself is air cooled.

|

Overview

The vacuum reflow oven is equipped with a hot

plate made of solid Aluminium, coated with ceramic. Another water

cooled plate is mounted beneath the hot plate. During cooling the

cold plate is lifted up and pressed against the hot plate, thus

cooling it quickly. This feature also enables cooling under vacuum.

|

OverviewInfrared lamps placed under (or optionally, above) the tooling plate heat it up. The tooling plate is in a rectangle form with dimensions 260mm x 210mm can be produced of any suitable material also with custom openings for fixtures inside it. Design enables loading of tooling plate inside the chamber together with the parts on it - this enables serial production. Process cooling by means of Nitrogen flow that blows from the chamber bottom against the tooling plate. The chamber itself is water cooled. An external water chiller is required if not ordered with mounting rack MR23CP |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Specifications

|

Specifications

|

Specifications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Datasheet |

Datasheets |

Datasheets |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

© PDP Equipment Ltd 2017

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||